What is the sensor size?

- Share

- Issue Time

- Nov 18,2024

Summary

Sensor size refers to the diagonal length of the sensing area on an industrial camera or image sensor that receives light signals, usually expressed in inches. However, the inch here is not the conventional definition of 1 inch equals 25.4 mm, but a historical standard, originally referring to the size of early camera tubes, approximately 16mm.

Sensor size refers to the diagonal length of the sensing area on an industrial camera or image sensor that receives light signals, usually expressed in inches. However, the inch here is not the conventional definition of 1 inch equals 25.4 mm, but a historical standard, originally referring to the size of early camera tubes, approximately 16mm.

Representation of sensor size

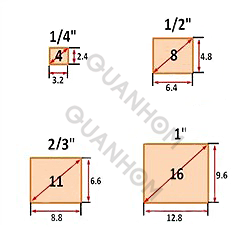

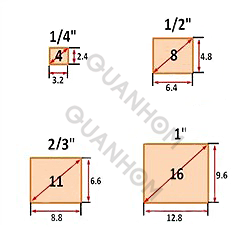

The representation of sensor size follows a specific standardization and may not strictly based on the ratio of 1 inch equals 16 mm. Common scales for rectangular sensors include 1:2, 3:2, and 16:9. To obtain the exact sensor size, you can calculate it by multiplying the resolution by the pixel size. Here are some common sensor sizes:

1 inch — Sensor size: 12.7mm (W) × 9.6mm (H), diagonal 16mm

2/3 inch — Sensor size: 8.8mm (W) × 6.6mm (H), diagonal 11mm

1/2 inch — Sensor size: 6.4mm (W) × 4.8mm (H), diagonal 8mm

1/4 inch — Sensor size: 3.2mm (W) × 2.4mm (H), diagonal 4mm

Calculation of sensor size

Sensor size can be calculated by the length of the long side and short side of the sensor using the Pythagorean theorem. And the long and short sides of the sensor are calculated by the pixel size and resolution, as follows:

Sensor long side (mm) = (Sensor long side pixels × Pixel size (μm)) ÷ 1000

Similarly, the short side can be calculated, and then the diagonal size can be determined using the long and short sides.

Importance of Sensor Size

In machine vision, the industrial camera is a critical component, with the image sensor serving as its most critical core element. And the size of the sensor directly affects the image quality. Generally, image quality is proportional to pixel size. This means that for image sensors of the same physical size, higher resolution results in smaller pixel sizes, which leads to lower image quality. For example, industrial 1/2.3‘ CMOS sensors usually have a resolution of only 5MP, while civilian 1/2.3’ CMOS sensors can have a resolution of 16MP or even higher. Therefore, the image quality of industrial cameras is often better than that of civilian cameras; at the same time, if the camera with the same resolution has a larger sensor area, the area of its unit pixel is also larger, and the image quality is also better. For the same 5MP camera, the image quality of the 2/3' sensor is better than that of the 1/2' sensor.

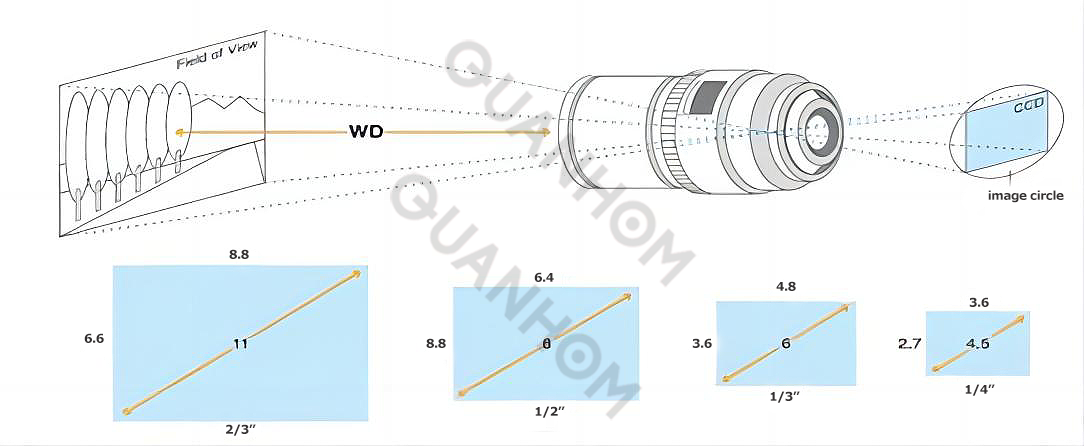

Sensor Size of Lens

It refers to the maximum sensor size that the lens is designed to support. If the camera sensor size exceeds the lens’s supported size, shadows or dark corners will appear in the image, meaning that the camera sensor’s edges will not be exposed to light. If the lens sensor size is too large, lens performance may be wasted. Given that the lens is circular, the lens sensor size is considered the lens diameter. The lens sensor area is calculated as: π*(Sensor Size)2 ∕4, the unit is mm2.

Matching sensor size of industrial cameras and lenses

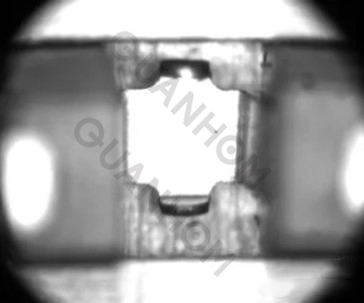

Both cameras and lenses have specified compatible sensor sizes, much like the image sensor’s own dimensions. Industrial lenses also have a maximum supported size, called the imaging size of the lens. Typically, the lens’s imaging size should be equal to or larger than the camera’s sensor size. If a smaller lens (for example, one supporting only 1/2" sensors) is used with a larger sensor camera (e.g., a 2/3" chip), a tunnel effect will occur at the edges of the field of view, resulting in black edges. The black areas cannot be imaged anyway, no matter how bright the light source is or how big the lens aperture is. The only area that can be imaged is a circular area inside, just like a tunnel.

Selection of Lens and Camera Sensor Size

The smaller the lens’s sensor size relative to the camera’s, the more pronounced the tunnel effect will be. The nominal maximum supported chip size of some manufacturers' lenses can actually support one level large. However, while the edges of the larger sensor may still display an image, the image quality and center ratio may be greatly reduced. It is generally not recommended to configure like this, unless the project does not require high-quality imaging at the edges and focuses primarily on the center field. .In such cases, as long as the edges display normally and do not impact overall imaging, using a lower grade lens may be a cost-effective choice.