What are the general design principles of the mounting base of the infrared optical lens?

- Share

- Issue Time

- Jul 23,2024

Summary

The bore diameter of the mounting hole of the infrared lens (D) should be larger than the outer diameter of the lens (d), and generally, for optic lenses, D is larger than d by 0.4 mm. On special occasions where there is a high demand of coaxality or athermalized design of the lens, the size of the mounting hole should be determined according to specific situations. The gap between them is for easier installation, and some silica gel can be filled in the gap to keep the lens from damage.

1. What are the general design principles of the mounting base of the infrared optical lens?

A. The bore diameter of the mounting hole of the infrared lens (D) should be larger than the outer diameter of the lens (d), and generally, for optic lenses, D is larger than d by 0.4 mm. On special occasions where there is a high demand of coaxality or athermalized design of the lens, the size of the mounting hole should be determined according to specific situations. The gap between them is for easier installation, and some silica gel can be filled in the gap to keep the lens from damage.

B. The tolerance range of the bore diameter of the mounting hole of the infrared lens usually follows the H8 standard. In some special cases, the grade of tolerance is higher, for it will make the optical axis adjustment easier in the assembling process.

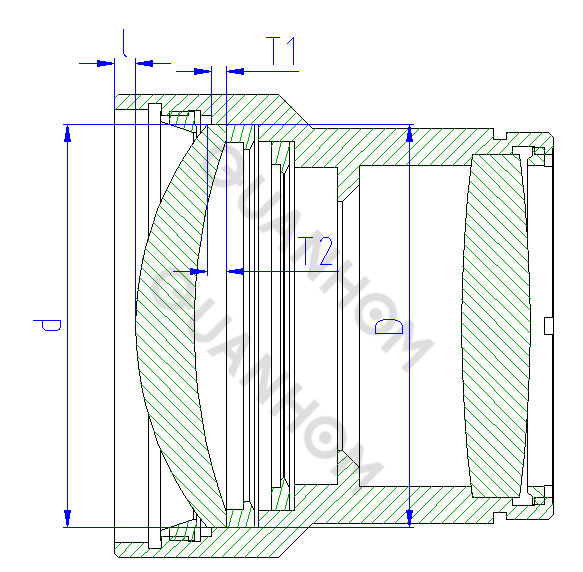

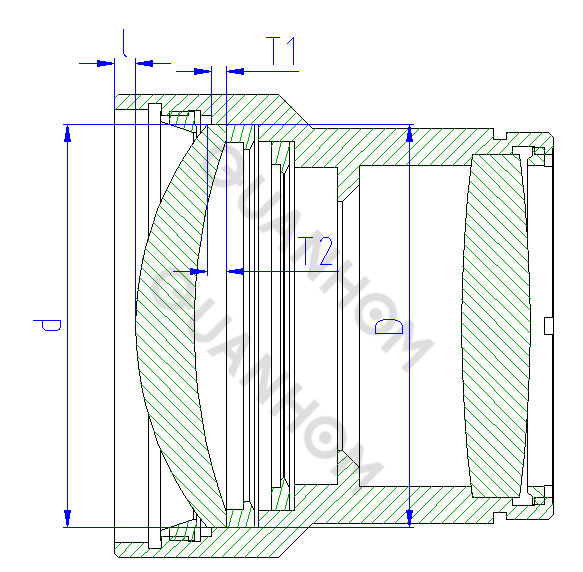

C. The relation between the axial dimension of the hole in the mounting base (T1) and the width of the outer diameter of the lens (T2) is as follows: T1≥2/3 T2.

D. There should be a space of 2-3 mm between the first vertex of the lens and the outermost end of the lens tube, which is mainly for protecting the lens and installing a lens cap.

E. The inner diameter of the structural component for fixing the lens must be larger than the clear aperture of the optical design.

F. The coaxality of the lens mounting holes and the degree of end face runout usually follow the grade 7 tolerance standard according to the size range.

2. How is the clamping ring for the infrared lens designed?

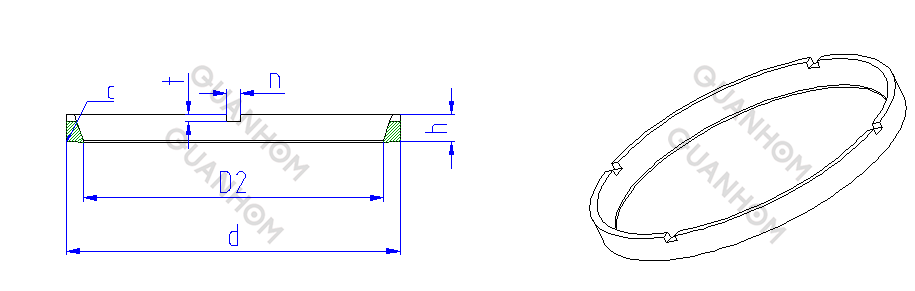

A. As is shown in the figure below, the structure of the clamping ring for the infrared lens is usually fixed, including the inner diameter (D2), the major diameter of the male thread (d), the thickness (h), the depth of the technology groove (t), the width of the technology groove (n), etc.

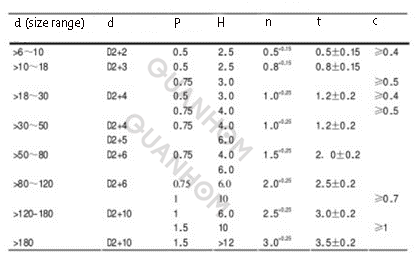

B. According to the size of the mounting base for infrared lenses, the size of the clamping ring can be selected from the chart below.

C. The inner diameter D2 is determined by the clear aperture, and its tolerance grade generally follows the H10 standard.

D. The strength and stiffness of the clamping ring must be high enough.

E. The inner ring should be combined with an extinction gear structure to prevent the influence of stray light on the imaging quality.

F. The clamping ring should be added with proper chamfering to make the thread easier to be screwed in.