The Methods for Testing Quality and Performance of Lens

- Share

- Issue Time

- Aug 12,2021

Summary

We can test the lens to judge its quality and performance. This article will specifically introduce the methods of testing the quality and performance of the lens.

Lenses have been widely used in all aspects of our lives. The vast majority of images we record and transmit, whether they are photos or videos, are inseparable from all kinds of lenses.

Regardless of the application, the image quality of the lens is of paramount importance. A high-quality lens is inseparable from perfect design and a precise manufacturing process. Once the design is finalized, the manufacturing process of the lens must be strictly controlled. The precision manufacturing process of the lens includes optical processing, mechanical processing, optical and mechanical assembly, and adjustment.

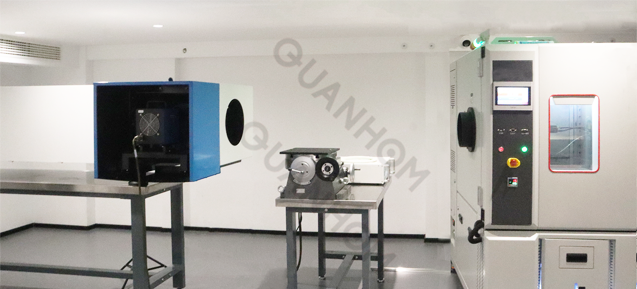

The errors in the manufacturing process of the lens sometimes will lead to a sharp drop in performance. Therefore, it is necessary to conduct a final performance test on the manufactured lens to eliminate the lens that cannot meet the quality requirements. The following is how to test the quality and performance of the lens.

Visual Inspection Lens

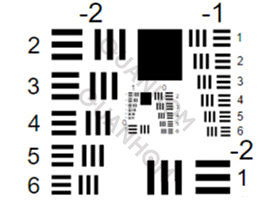

Visual inspection of the image quality of the lens is one of the methods to ensure the quality of the lens, such as the star point hole test (observing the pinhole image), the resolution map (observing the periodic line diagram with different spacing), and the projection test (using the lens to change the test chart The image is projected on the screen) and other tests.

However, these have a common shortcoming-they rely on the subjective judgment of the observer. Even experienced observers can hardly make consistent judgments, and the judgment standards between different observers are extremely different. In addition, there are often some problems in the correlation between these tests and the final application, and these test results are difficult to effectively guide the design to investigate and solve the problems in the processing process.

USAF-1951 identification rate board

Modulation Transfer Function (MTF) Test

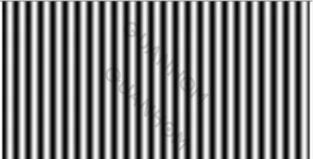

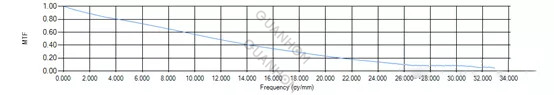

In order to avoid the problems caused by these subjective tests, most manufacturers currently use the method of testing the modulation transfer function (MTF) to objectively evaluate the quality of the lens. MTF uses sine targets of different frequencies to test the lens. The sine target is a periodic pattern composed of black and white bars, and the change from black to white is a sine curve. The change from black to white is called contrast, which is measured as a percentage of light intensity. When the lens images these targets to its focal plane, the image is a sinusoidal pattern with reduced contrast.

100% contrast ratio (MTF=1)

50% contrast ratio (MTF=0.5)

10% contrast ratio (MTF=0.1)

The number of cycles (or line pairs) per millimeter is called the spatial frequency of the target. For low-frequency targets, the line spacing is larger, and the contrast reduction amplitude is also small, but as the line spacing decreases and the spatial frequency increases, the contrast in the image usually decreases to zero, and the imaging spots in the image are uniform and gray.

The frequency at this time is called the cut-off frequency of the lens (in fact, if understood from the electronics point of view, the lens can be regarded as a low-pass filter), MTF is defined as the image contrast formed by the lens and the target contrast expressed as a spatial frequency function ratio.

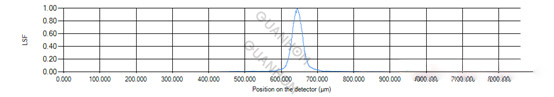

In the actual MTF test process, the measurement usually uses a basic target (such as a point, a line, or an edge), and then use a camera system or a scanning detector to measure the intensity distribution of the corresponding image, and use the Fourier transform method to calculate the image Average modulation transfer function. The following figure shows the point spread function PSF obtained through testing and the MTF obtained through fast Fourier transform.

PSF and MTF

MTF is not only a quick and objective measurement method for evaluating lens imaging quality, but also can compare the measurement results with design expectations, achieve "closed-loop control" on lens design, and study the performance differences between design and manufacturing and their causes.

It should be pointed out that MTF is not a single metric but depends on the imaging area of the lens under test, that is the field of view of the lens. Generally speaking, a lens performs best in the center area of the field of view, and gradually decreases toward the edge of the field of view. Therefore, MTF testing should be performed at a different field of view positions to ensure that the performance of the entire image area is acceptable.

The infrared optical lens designed and produced by Quanhom has undergone strict MTF testing to ensure the quality and performance of the lens. If you want to know more about infrared optical lenses after reading the above content, you can get a comprehensive solution by contacting us.

As a professional manufacturer of Opto-electromechanical components, we are committed to producing various infrared thermal imaging lenses (including LWIR, MWIR, and SWIR). We have an experienced production team and a strict quality inspection system to conduct strict tests and inspections on the quality of our products, which has won unanimous praise from many customers. We always put the needs of customers in the first place and can provide customers with effective solution technology and thoughtful one-stop service, If you are interested in our infrared optical lens, please contact us immediately!